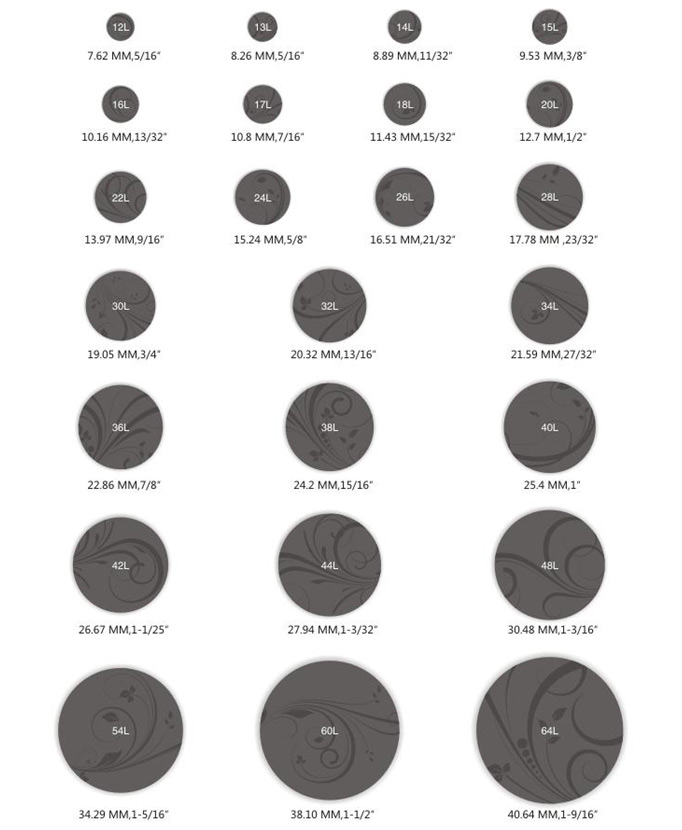

1.Button size lignes (L) or millimeter(mm) for diameter

1 Lignes = 0.635mm 1mm =1/25.4 inch

|

12L=7.62MM=5/16” |

13L=8.26MM=5/16” |

14L=8.89MM=11/32” |

|

15L=9.53MM=3/8” |

16L=10.16MM=13/32” |

17L=10.80MM=7/16” |

|

18L=11.43MM=15/32” |

20L=12.7MM=1/2” |

22L=13.97MM=9/16” |

|

24L=15.24MM=5/8” |

26L=16.51MM=21/32” |

28L=17.78MM=23/32” |

|

30L=19.05MM=3/4” |

32L=20.32MM=13/16” |

34L=21.59MM=27/32” |

|

36L=22.86MM=7/8” |

38L=24.20MM=5/16” |

40L=25.40MM=1” |

|

42L=26.67MM=1-1/25” |

44L=27.94MM=1-3/32” |

48L=30.48MM=1-3/16” |

|

54L=34.29MM=1-5/16” |

60L=38.10MM=1-1/2” |

64L=40.64MM=1-9/16” |

Remark:Measurement of lignes is not exactly 100% equal to mm

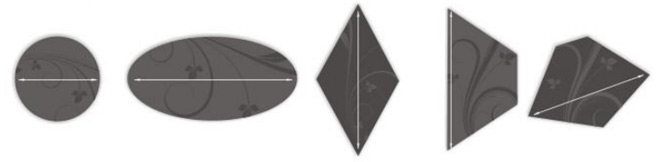

2.Correct measurement of buttons

For button size,measure the outer largest diameter

3.Number and unit of buttons

Piece PC.=1PC

Dozen D.=12PCS

GROSS G.=144PCS

GREAT GROSS GG.=.=1728PCS=12G

4.Button classification

|

Natural substance |

Chemical substance |

Other substance |

|

Shell button |

Resin button |

Metal button |

|

Corozo button |

Urea button |

Leather button |

|

Wood button |

Plastic button |

Cloth buckle |

|

Horn button |

Ceramic button |

/ |

5.Standard of finished button

a)The color, pattern and model should be the same as the sample or the product.

b)The pinhole is correct and symmetrical, and the needle distance and pinhole size meet the standard.

c)Luminosity meets the requirement.

d)The button is not cracked and uneven thickness phenomenon.

e)The surface of the button should not be cracked, notched and obvious scratches.

a) When the opening and closing is not smooth, if the chain head is pulled forcefully, the teeth will can't align with e...

Take moreThe dye in the zipper tape may react with organic materials such as plasticizer in fabrics that contain PVC coating to p...

Take morea) Zippers should be sewn without bending and kept straight. A certain channel is reserved between the chain teeth and t...

Take more